The Bee Hive

Honeybees naturally live in places where there is space and safety for them such as a cavity in an old tree, or wall, or a roof space which provides protection from predators and the elements. Beekeepers keep colonies of bees in hives, artificial homes offering the same conditions, and are generally made of red cedar wood or high density polystyrene. There are many different types available, some easier to use than others however successful beekeeping is down to the skill of the beekeeper rather than the type of hives used. For the beginner it is best to chose one of the more commonly used hive types, such as the ‘National’ or ‘Smiths’ types, so that getting extra components, spares and replacements is easy. Either of these two types are very good, it is simply a matter of personal choice, but chose one type and stick with it.

Bee Hives - Summer and Winter

Hives and colonies need looking after in all seasons.

There is always a bit of trade going on with second hand bits, but be sure of what you are buying. Whatever type of hive you have, know how to recognise the different components, and their dimensions, that’s very important. Your bees will build comb in which to house the brood and to store supplies such as honey, pollen and nectar, and they are extremely efficient at it, and very very precise in terms of measurement and construction. Hive components should always be to the recommended type and dimensions. Always sterilise any second hand components before use.

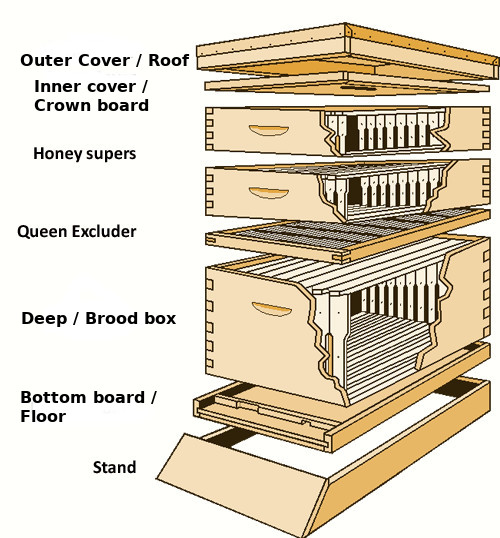

Typical Hive Components

Hive Components Description

A typical hive will have the following components:

- A stand of some description, can be purchased or cobbled up, as long as it is secure and keeps the hive off the ground and air circulating

- A floor or bottom board. A ‘varroa floor’ is recommended and has a mesh base and a removable board to enable debris inspection and cleaning (more on that later)

- A brood box (or deep) with the correct number of frames (usually 11) with wired foundation to support the comb, brood and some stores.

- A queen excluder, usually wire or a plastic mesh specifically designed to let worker bees through but to keep the queen and drones out of the honey storage area

- A honey super (or shallow) with the correct number of frames with foundation wired or unwired (more on this later) for the honey to be stored in. A good going colony in a good year might need three of these one on top of the other! You can never have enough honey supers.

- An inner cover or crown board/clearer board, usually with a hole which will take a feeder or a clearing device when necessary.

- A lid (roof) with a weatherproof covering, these usually come with a tin covering, but mineral felt is just as good.

- A supply of bricks or flat stones to weigh down the lid to stop it blowing off, a couple of bricks usually does it. Weights may not be suitable for use on polyhives, a heavyweight base and ratchet straps is an alternative in this instance.

You can never have enough gear! It’s best to have spares at hand rather than finding out that you need something when you are in the apiary all suited up with the hive open and the air full of bees! At least two of everything is essential, and it’s amazing how much stuff you accumulate over time.

Inside the Hive

Beeswax - The main honeycomb building material is beeswax, secreted from glands on the bees bodies as tiny scales. It consists of mainly This is used to construct the honeycomb, the hexagonal cells. They will build comb from scratch if necessary but beekeepers tend to fill frames with foundation (a flat sheet of wax with the hexagonal shape embossed across it) to give them an easy start and to get the comb in the right place. New comb is cream white in colour and darkens over time and use in the hive. The comb creates the main structure of the bees nest, and houses the brood and stores of honey and pollen.

Propolis - The other material that bees use is propolis, a sticky substance that they make using tree resin and which they use to stick things together, fill small gaps, and to strengthen things. It is dark in colour, very sticky, is quite difficult to remove and has a distinctive but not unpleasant smell. Hive components should fit together correctly, drafts are a major problem especially in winter. Brood (eggs and larvae) need to kept at between 32 and 36 degrees Centigrade, and they are easily chilled and die.

Beespace - This is the space that the bees move around in within the hive, and they are very particular about how much space there is between things. Beespace is widely recognised as being between 4.5mm and 8mm depending on whether the situation requires bees working individually or back to back. Hive components are designed with this in mind so no need to worry as long as you are using the correct type for type components.

Bees spend a lot of time measuring, and if there is a small space or gap they are not expecting they will fill it with propolis (the sticky substance they make from tree resin), and if the there is a large gap they will fill it with brace comb (bees wax) making hive manipulations tricky. Hive components are designed to allow the correct beespace between components and between upper honey supers and the lower brood boxes.

Frames and Foundation

Wired or un-wired foundation, an important choice.

Frames and Foundation - The frames that go inside the deeps and shallows are specific to the type of hive in terms of length and height. However the cells structure created be the bees is always the same. You normally buy frames in self assembly packs and they are straight forward enough to assemble but only use the correct frame nails and in the correct manner. The assembled frames are filled with foundation, a flat sheet of wax with the hexagonal cell shape embossed across it. The foundation should be of the correct dimensions for your type of frames. Once the bees have built (or drawn) the comb onto the foundation they will put it to immediate use for brood or stores.

Foundation is easily damaged, filling frames with foundation shouldn’t be carried out on very cold or very hot days. There is a knack to this and it is usually part of the beginners classes, but if you chose not to go to classes a mentor will show you what’s what.

Two qualities of foundation are available, both are good, and can be wired or un-wired. The wired type is normally used in the deep brood box to give the comb extra support during manipulations, and in the honey supers when you are going to harvest honey by using a spinning extractor. If you are going to use the crush and filter method of harvesting honey then un-wired is best in the supers. How you harvest the crop is a personal choice. Always collect old and used wax to trade in for new foundation.

Hive Types

There are many types of hives available, are all good enough in the hands an experienced beekeeper and they are very much a matter of personal choice. Every beekeeper extols the virtues of the type they prefer to use, but success is more down to skill and expertise than hive design. The following are notes on some of the more notable designs.

The Skep

A modern skep made from straw being used to take a swarm.

Sometimes known as a 'Ruskie' in Scotland, the skep was the original container used for keeping bees on the farm or estate, and easily made by the beekeeper from local straw, willow, or heather. They are the traditional upside down dome shape and were protected from the elements with whatever was available, or kept in alcoves in walls known as 'Bee Boles'. Harvesting the honey necessitated evicting the entire colony from the skep, sometimes by drumming them out with a stick. It was a wasteful method and particularly unkind and destructive to the bees. Skeps can still be purchased and are often used for taking swarms.

Removable Frame Hives

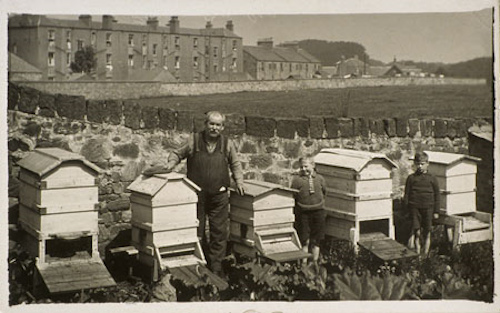

From the humble skep to the double skinned WBC removable frame hive there have been many innovative designs and techniques used in keeping hived bees, brought about over the years by observant and enterprising beekeepers, many of whom in the early days would most likely fashion their own following the popular designs of the day.

A 1920s image of a Roslin beekeeper (© Midlothian Council Archives), his various removable frame hives, and apprentices! The hives are south-facing behind a wall and at the edge of a rhubarb plantation - shelter, maximum exposure to sun, and heat retained by the stonework all contributing to year round success. For the observant beekeepers the big question is did Mr Young of Roslin know that the rhubarb plants gave off oxalic acid fumes that would help deter pests in his hives?!!

The hives in the image are all similar in style but quite different in dimensions, possibly different manufacturers or all home made, and the components would not be easily usable between the other hives.

The Langstroth and Modified Dadant Hive

Modern Langstroth hive with pitched roof, alternatively supplied with a flat roof.

Lorenzo Langstroth is largely credited with discovering the 'bee space' and inventing the vertical, modular, removable frame, wooden hive system widely used today in the 1850s. It involved standard sizes and interchangeable hive components. Langstroth and Dadant hives are usually 10 to 12 frame styles and are a larger design suited to the prolific bee strains found in America, and although found in the UK are not particularly suited to UK bees. Prior to Langstroth it is likely that many beekeepers came up with their own particular wooden alternatives to the Skep. Most hive manufacturers today use the Langstroth system in their design.

The National Hive

A popular and widely used hive, supplied with flat or pitched roof.

In the post war years of the 20th century interchangeability was becoming fashionable and beekeepers started moving from the popular double walled W.B.C. when hive manufacturers started to produce cheaper single walled hives with standardised frame sizes and components to suit. So many patterns emerged that in the mid 1930s the Ministry of Agriculture and Fisheries moved to create a formally recognised 'British Standard'. Patterns were submitted to a panel of experts appointed by the National Mark Honey Trade Committee who selected one, with some slight modifications, that would become the standard. The one chosen was already being produced by several manufacturers under different names and was duly adopted and renamed the 'National' that we recognise today.The 'National' hive design comprises a double wall design front and rear, with finger grips cut into the outside, and featured the long lug type frames and bottom bee space. This was later modified to have hand grip bars either side of the boxes to make lifting easier. The National uses the Langstroth vertical system of a floor, a deep box for brood, and queen excluder, a shallow for honey stores, a crown board, and a roof.

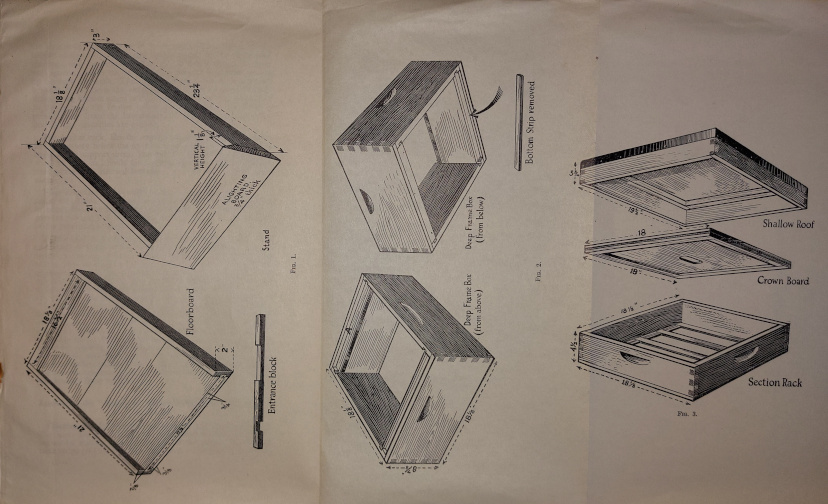

The "National" Single Walled Hive design detail from The Ministry of Agriculture and Fisheries' 1935 Marketing Leaflet No. 79.

The Smith Hive

A popular hive in the Scotland, compact, and convenient for migratory beekeeping

Developed in the late 1920s following 30 years of research into British and American methods, prominent Scottish Beekeeper William W. Smith of Innerleithen, one of the very first commercial beekeepers, introduced his own hive design to the beekeeping world. It had the same internal dimensions to what became the National Hive, but lacked the double front and rear walls, and featured 11 short lug frames and top bee space, making it a simple compact design very popular in Scotland and Northern England where migratory beekeeping to the heather is practised. By the mid 20th century it had become very popular and was soon adopted by the British Standards Institution. The Smith Hive was awarded the Royal Highland Show 1st prize at Paisley 1950, Aberdeen 1951, Kelso 1952, Dumfries 1954, and Edinburgh 1955. Nathaniel Grieve of Edinburgh (descibed below) collaborated with Willie Smith and specialised in the production of the Smith Hive which in 1956 cost 66/- (66 shillings, or £3.30 in new money!) for a stand with alighting board, flush floorboard, entrance block, brood chamber, and shallow alluminium covered roof. Supers and frames were extra. The 'Smith' Combined Cutter-Scraper used in preparing heather honey combs for pressing is another Willie Smith invention. It cost 14/7 (14 shillings and 7 pence) in 1951, that's just under 75p in new money, and costs over £32 today!

The National and Smith Hives they are the two most popular hive designs used in the UK today.

The Polyhive

An unpainted polystyrene version of the National Hive, increasing in popularity.

Polyhive components are moulded in one piece from a high density polystyrene which makes them lighter in weight than wooden hives. They offer good durability, greater winter insulation and can be painted. They come in most hive type versions and are often interchangeable with most wooden hive components of the same type. They are widely used today and receive mostly favourable reviews however an area of concern is the amount of brood they may sustain during the winter months and the effect that has on varroa populations.

The WBC Hive

To most this is the classic white beehive, and is still popular but costly.

William Broughton Carr designed this hive with the damp UK weather in mind in the late 1800s, and comprises a stack of light weight inner boxes surrounded by a stack of outer shells (lifts) to give extra insulation making it quite a substantial construction. The frames are of British Standard size, however due to the double skinned nature of the assembled hive, it is difficult to transport colonies, is big and very heavy, and is more costly requiring more components than the alternatives. It was at one time very popular in the UK. The original WBC design has changed over the years but is still available and in use today.

The Glen Hive

A big double skinned hive with an under floor entrance for the bees.

This was another Scottish invention at the turn of the 20th century, and utilised the WBC double skin stacking design but with an under floor entrance and 15 British Standard deep frames to accommodate larger colonies for the heather moors. These are very large hives and are not easily moved but could be very productive in the right place.

The Warré Hive

A 'natural' beekeeping system devised by Abbé Émile Warré (1867-1951)

Warré hives, known as the 'Peoples Hive', have been around from the mid 20th Century and have become popular due to their design and use which replicates more closely a natural bee nest as it would be in a tree trunk. The design principal focuses on the bees needs more than the beekeepers and operates a foundation-less system where the bees build from wooden bars in the top of the box. As in nature the bees use the top part of the drawn comb for storing honey and the lower for brood, and only needs opening once a year.

The Top Bar Hive

Also known as the Kenyon Hive, is a low tech system of beekeeping, but requires a good level of beekeeping knowledge and experience.

Another alternative way to keep bees and produce honey, working on the principal of letting the bees do what comes naturally, and is a fairly low-tech way to keep bees, but requires a good level of beekeeping knowledge and expertise. The hive has no frames or foundation but uses top bars packed together instead of a crown board. The bees free range inside the bee space and build their nest from scratch from the underside of the top bars.

Hive Types and Manufacturers

There have been a wide range of manufacturers and types of bee hive in the UK, some still manufactured and some out of production, many using the British Standard frame sizes, and others that didn't. Burgess & Son in Exeter, Steele and Brodie in Wormit Fife, E. H. Taylor in Welwyn Herts (acquired by E. H. Thorne in 1984) were notable manufacturers of the day. Beekeepers have long been known for their inventiveness and during the move from Skep to removable frame hives, there were probably as many individual designs as there were beekeepers.

Detail from a WBC hive roof front made by Steele & Brodie Ltd, Fife.

Wormit Commercial Hives were made by Steele & Brodie Beehive Works in Wormit, Fife (Est 1870s, closed 1998). They were very popular with commercial beekeepers due to their stout construction and interlocking weather-proof design, some are still in use today. The company also made other versions of hive including the WBC hive which had a flat rear sloping roof with bee escapes as seen the above image.

Makers label on a Grieve Hive roof section, made in Edinburgh and were very high quality.

Grieve Beehives and Appliances were made by Nathaniel Grieve Builder and Joiner, Washington Lane, Dalry, Edinburgh (Est 1867, closed 1960s). They were a well known and highly regarded company that carried out notable works on many prominent buildings in the city and beyond. They started to make hives when business was quiet, manufacturing very high quality hives to the popular Smiths, National, and W.B.C. designs of the day. The above image is the name tag on the roof of a Smith type design hive still in use today, its probably 70 years old or more, and still serviceable.

Nathaniel Grieve 1956 Catalogue cover detail.

Beekeeping On The Continent

Slovenian Beehouse

An eighteen hive Beehouse in a Slovenian beekeepers garden.

On the continent where the climate and countryside is considerably different to ours beekeepers use other types of removable frame hives to suit their needs. Beehouses are not uncommon and are a means of keeping many colonies together in the one place. They can be permanently located in situ' or mounted on a vehicle allowing migratory beekeeping. The image above shows a Beehouse in Postojna with its traditionally decorated front panels, each hive with a different motif design or 'panjske končnice' depicting biblical or folklore scenes. Decorating hives has been a tradition in Slovenia since the 1700s. The AŽ design (Anton Žnideršic) hives are accessed from inside the Beehouse.

Home of Beekeeping

It's said that Slovenia is the worlds home of beekeeping, when around 1 in every 200 people is a beekeeper in a country with a population of just 2 million, who would disagree? Nestled in amongst the Dinaric and Julian Alps to the north of the Mediterranean, bordered by Austria, Hungary, Croatia, Italy, and the Adriatic Sea, Slovenia enjoys a climate that is warm in summer (avg 20℃) and cool and fresh in winter (avg 0℃), an exceptional range of habitats and correspondingly high biodiversity. Add to that the native Carniolan Honeybee, apis mellifera carnica, well known for it's resilient, hard working, and good tempered attributes, it's no surprise that beekeeping is a significant part of Slovenian culture and heritage, something that they are quite rightly very proud of.

Inside an immaculately kept Beehouse showing the the arrangement of the AŽ hives.

AŽ hives are specifically designed to be used in Beehouses with access to the two sections through a door at the rear. The upper (honey) and lower (brood) sections are separated by a queen excluder and the individual frames easily slide out on runners. There are no removable supers or deeps in this design, one advantage being there is no heavy lifting involved. The AŽ / Beehouse system requires regular attention with filled honey frames individually harvested and replaced quickly, with similar attention in the brood section for swarm prevention.

A new AŽ two section hive viewed from the rear. The top door vent is folded open and the screens are in place.

The image above shows a new hive with its rear inspection door open. The door is removable and has closable top and bottom vents. The rear mesh screens and frame spacers are removable for access to the top honey section and lower brood chamber. With the screens in place the colony can be viewed without releasing the bees.

AŽ two section hive interior arrangement with door, screens and spacer bar removed.

The AŽ hive has a simple design and are commonly the two or three section versions.The rear inspection door which has top and bottom closable vents can be opened and fully removed for maintenance of the frames which sit on steel support runners and are kept aligned by spacer bars front and rear. The frames are simply pulled out, sliding across the runners. The image shows a 2 section hive open with the rear spacer and screens removed showing the 10 frame arrangement and queen excluder, a removable varroa mesh floor fits below the brood frame runners.

Older style Slovenian hives with a simple design that were stacked on shelves in earlier type bee houses.

Innovation

Beekeeper's skill-sets often include being a bit of a carpenter, engineer, scientist, chemist, vet, inventor and entrepreneur. Innovation is often the product of these. With beekeeping so integral in Slovenian culture it is not unusual for keepers to challenge themselves, solving problems or coming up with something completely different.

Tree Stump Hive

A novel design hive making an attractive garden feature

Made using a simpler AŽ type hive design, an upside-down tree stump, bracket fungi, some modern roofing materials and no small amount of skill and imagination to produce a very attractive yet functional garden feature.

The colony is managed similarly to the beehouse hives and is accessed through a door at the rear.

Honeycomb, made in the Jar

Ingenious planning to get bees working inside the honey jar.

Getting bees to build and fill comb inside a jar is no mean feat. The 900g jars were filled with comb and honey by the bees then later topped up with liquid honey.

About the 'My Beekeeping Kit' website.

Contact Iain Dewar for enquiries, suggestions, corrections and contributions for improving the notes. Always welcome!